MS-50GT

HIGH SPEED PRODUCTION CONSOLE

HELIUM LEAK DETECTOR

The MS-50GT is a highly technical system that incorporates many sophisticated technologies. In view of this, every effort has been made to automate the unit’s operation and maintenance procedures. The MS-50GT is an automated high-speed production console leak detector featuring three flow modes which provide flexibility and maximum productivity for application-specific leak testing.

It also meets the stringent requirements for robustness, reliability and ease of maintenance that are essential in any industrial environment..

MS-50GT: APPLICATIONS

Characteristics

- Sensitivity, vacuum*: 3.0×10-11 (atm-cc/sec)

- Sensitivity, sniffing: 1.0×10-08 (atm-cc/sec)

- Leak Measurement Range: 3.0×10-111 to 10

- Leak Ranging: Auto/Manual

- Startup Time: Less than 3 minutes

- Response Time *: <2 direct <2.5 reverse

- Resolution for 4He*: 14 at mass 4

- Gross Test Time (with UFT Option): – 3 (100 Torr)(seconds)

- Fine Test Time (with UFT Option): – 10 (25 mTorr, 10^-10 atm-cc/sec)

- Mass Spectrometer Tube: 180° deflection; dual-magnetic sector

- Auto-tuning

- Auto-calibration: Internal; External – auto

- Auto-zeroing: Several zeroing functions

modes for background suppression - Reject set-point

- Built-in calibrated leak: 10-08 range

NIST traceable: Yes - Temperature compensated

- Scan/Descan

- Filaments: 2 Thoria Coated Irridum

- Testable Masses: 3+4

- Background Compensation:

- Automatic

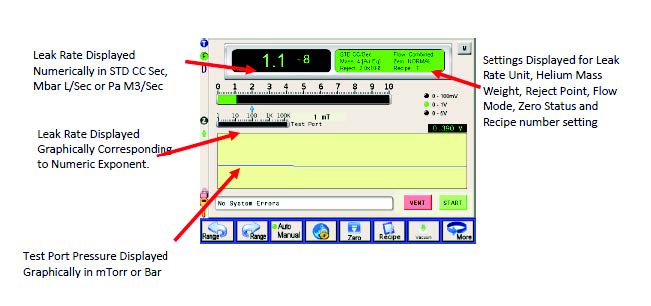

Maximum Operating Pressure: 100 mTorr, 10 Torr reverse - Display/Interface: 10 (25.4) LCD flat panel display, capacitive

touch-screen / Graphical - User Interface (GUI Units: cc/second, mbar*l/second, Pa*M3/second

- RS-232C

- Software: 50 programmable test recipes; Data Link optional

| Measurement Characteristics |

|---|

| Sensitivity Vacuum | Sensitivity Sniffing | Startup Time |

|---|---|---|

| 3.0×10-11 (atm-cc/sec) |

10-3~10-5 Atm-cc/second |

Less than 3 minutes |

Available Models

- Dual Port

- Ultrafast (UFT)

- Oil-based

- Dry Pump

- High Sensitivity

- Argon Gas

| Technical Specifications |

|---|

| Power | 115/50-60/30; 230-240/50-60/15 100/50-60/30 V/Hz/A |

|---|---|

| Dimensions | (W x H x D): 25.75 x 30.625 x 35.25 (65.40 x 77.79 x 89.54) |

| Weight | 475 lbs, 215.45 kg |

| Vacuum Mode | Direct, reverse or combination, gross testing |

| Roughing Pump | 16 direct drive (cfm) |

| Test Port Connection | 1.125 (inches) |

| High Vacuum Pump | 53 L/sec |

| Vacuum Gaughing | Pirani: Test Port and Foreline Ion: Hihg Vacuum |

| Cold Trap | MS-50GT – N/A MS-50GT Dry – N/A |

| Test Cup, UFT Option UFT(Ø x D) |

Dimensions (in mm) W344*H395*D618 |

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.